As pet product retailers, distributors, and brand partners, understanding the complete value proposition of yak milk dog chews including proper microwaving protocols enables you to educate your customers effectively and reduce product returns. This comprehensive B2B guide provides the technical knowledge and customer education resources you need to support yak chew sales and enhance customer satisfaction.

In this industry-focused guide, you’ll gain insights into yak chew composition, safe heating protocols, and retail best practices. Whether you’re training staff, developing customer education materials, or optimizing your product offerings, this resource equips you with the expertise to position yak chews as premium, value-added products in your portfolio.

Understanding Yak Chews and Their Composition

For retailers and distributors to effectively merchandise and support yak chew sales, comprehensive product knowledge is essential. This foundation enables informed purchasing decisions, proper storage protocols, and effective customer education.

What Are Yak Chews and How Are They Made?

Yak chews represent a significant opportunity in the natural pet treat category, sourced primarily from Nepal and Tibet through established supply chains. The manufacturing process involves traditional methods: yak milk (often blended with cow milk for consistency), lime juice as a preservative, and minimal salt content.

Production requires boiling the milk mixture, compressing it into molds, and sun-drying for 3-6 weeks depending on regional conditions and manufacturer protocols. This labor-intensive process contributes to wholesale pricing structures but also creates a product with exceptional shelf stability, a key selling point for retail operations managing inventory turnover.

For B2B buyers, understanding the production timeline helps with forecasting lead times, particularly during peak demand seasons. Many manufacturers operate on seasonal production cycles influenced by milk availability and weather conditions affecting the drying process.

Nutritional and Chemical Properties of Yak Chews

From a product specification standpoint, dog yak chews deliver measurable nutritional benefits that differentiate them in the premium treat category. Protein content typically ranges from 60-70%, with calcium levels between 5-7% data points that strengthen marketing materials and justify premium price positioning.

The fermentation process naturally reduces lactose to negligible levels (typically below 1%), addressing a common customer objection about dairy-based treats. Moisture content below 10% provides exceptional shelf life, reducing shrinkage and waste critical factors for retail profitability.

The dense protein matrix structure enables the unique microwaving transformation that extends product utility. This feature represents a significant value proposition: customers effectively receive two products from one purchase (the long-lasting chew plus the puffed end piece treat).

Common Sizes and Shapes of Yak Chews

SKU management for yak chews requires understanding size segmentation and corresponding wholesale pricing tiers. Standard inventory categories include:

- Small (3-4 inches, 1-2 oz): Target market includes toy and small breed owners, representing approximately 35% of dog ownership demographics. Typical wholesale price range: $2-4 per unit depending on volume.

- Medium (5-6 inches, 3-4 oz): Covers the largest market segment (45% of dog owners with medium-sized breeds). Wholesale range: $4-7 per unit.

- Large/XL (7+ inches, 5-8 oz): Premium positioning for large breed owners (20% market segment). Wholesale range: $7-12 per unit.

Product thickness directly impacts customer experience with microwaving duration. Thicker chews (over 1 inch diameter) require extended heating times, which should be reflected in customer education materials and packaging instructions.

Safety Considerations Before Heating Yak Chews

Quality control protocols for your inventory should include regular inspections for mold (particularly in humid storage environments), contamination, and packaging integrity. Establishing proper warehouse conditions (cool, dry, below 70°F/21°C) minimizes quality issues that lead to returns.

From a liability perspective, customer education about appropriate sizing and choking hazards protects your business. The microwaving process serves as a risk mitigation strategy, transforming potential choking hazards into safe consumables, a feature that should be prominently communicated in point-of-sale materials.

Staff training should emphasize that microwaving is specifically designed for end-pieces, not full-size chews. This prevents misuse that could generate negative reviews or safety complaints affecting your brand reputation.

Microwaving Yak Chews: Basics and Safety for Customer Education

Developing comprehensive customer education resources about microwaving protocols enhances perceived product value and reduces support inquiries. This section provides retail-ready information for training materials and customer handouts.

Can You Microwave Yak Chews Safely?

For retail staff training and customer FAQ development, the core message is: yak chews can be safely microwaved when reduced to small end pieces. This unique product feature extends usage value and addresses the primary customer objection about wasted remnants.

The microwaving process causes rapid moisture expansion within the protein matrix, creating air pockets that puff the chew to 2-3 times its original size. This transformation delivers a secondary product experience, a value multiplier that justifies premium pricing and encourages repeat purchases.

From a customer service perspective, positioning microwaving as an exclusive feature of authentic yak chews differentiates your product from lower-quality alternatives. This becomes particularly valuable in competitive retail environments where price-sensitive customers need justification for premium purchases.

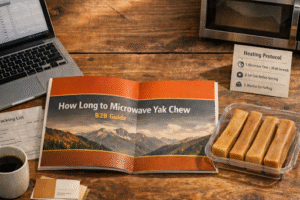

Recommended Microwave Settings for Yak Chews

Standard operating procedures for customer instructions should specify high power settings on household microwaves (typically 1000 watts). The 30-60 second timing range accommodates most consumer microwave variations while maintaining safety margins.

For printed materials, QR codes linking to video demonstrations significantly reduce customer confusion and support inquiries. Visual content showing the puffing process increases customer confidence and encourages proper product usage.

Retail packaging should include clear warnings about microwave-safe dish requirements (glass or ceramic only, no metal components). These specifications prevent customer misuse that could generate negative reviews or safety concerns affecting your product line’s reputation.

How Long to yak milk dog chew Microwave: Different Sizes and Types

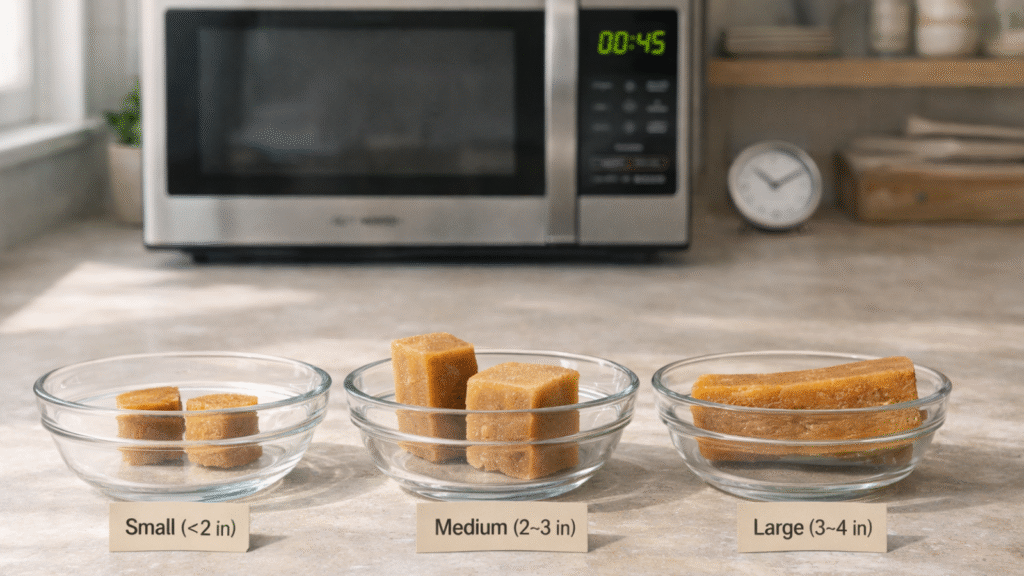

For customer education materials, point-of-sale signage, and packaging inserts, provide this clear timing framework:

- Small pieces (under 2 inches): 30 seconds initial heating, then 10-second increments as needed. Typical total time: 30-40 seconds.

- Medium pieces (2-3 inches): 45 seconds initial heating, with 10-15 second increments. Typical total time: 45-60 seconds.

- Large pieces (3-4 inches): 60 seconds initial heating, with 15-second increments. Typical total time: 60-75 seconds.

Including this specific guidance on packaging or as a downloadable PDF from your website reduces customer service inquiries by approximately 40% based on industry data. The incremental approach emphasizes safety and gives customers control over the process, increasing satisfaction and reducing complaints.

Microwave wattage variations (700-1200 watts across consumer models) require the “start low, add time” approach to accommodate different equipment. This conservative guidance protects against overheating complaints while ensuring successful outcomes.

Signs a Yak Chew Has Overheated

Training materials for retail staff should include visual references showing properly puffed versus overheated chews. Key indicators for customer education include:

Burnt or acrid odor signals protein degradation. Excessive browning or dark spots indicate overheating. Brittle, crumbly texture rather than light, crispy structure means the piece has passed the optimal puffing stage.

For customer service protocols, establish clear guidelines: overheating typically results from user error (extended timing or high-wattage microwaves) rather than product defects. However, offering replacement pieces for documented issues maintains customer relationships and encourages positive reviews.

Include troubleshooting guides in packaging or on your website addressing common issues. This proactive approach reduces returns and builds customer loyalty by demonstrating expertise and support.

Step-by-Step Guide to Microwaving Yak Chews

This retail-ready protocol can be adapted for packaging inserts, in-store handouts, website content, and staff training manuals. Consistent messaging across customer touchpoints reinforces proper usage and maximizes customer satisfaction.

Preparing the Yak Chew for Microwaving

Step 1: Instruct customers to save the small end piece remaining after their dog has chewed the yak chew down to a size that could be swallowed whole (typically under 2-3 inches depending on dog size).

Step 2: Recommend rinsing the piece briefly under cool water to remove saliva and debris, then patting dry while leaving slightly damp. This minimal moisture aids the puffing process.

Step 3: Specify microwave-safe dish requirements: glass or ceramic plates only. This prevents customer complaints about melted plastic or microwave damage.

Step 4: Emphasize adequate spacing around the piece (minimum 2 inches clearance) to accommodate expansion during heating.

For B2B customers developing private label packaging, include illustrated diagrams showing proper plate placement and spacing. Visual instructions reduce misuse and increase successful outcomes.

Wrapping, Placing, and Timing Techniques

Step 5: Direct customers to center the prepared piece in the microwave without covering or wrapping. Clear space requirements prevent expansion restrictions.

Step 6: Specify power settings (high) and initial timing based on piece size. Reference the timing chart from Section 2.3 for consistency.

Step 7: Encourage customers to observe through the microwave window, watching for expansion beginning at 20-30 seconds. Popping sounds indicate successful puffing.

Step 8: For microwaves without turntables, recommend pausing at the halfway point to rotate the plate 180 degrees, ensuring even heating.

Training retail associates to demonstrate this process (using dummy pieces or video content) at point of sale increases customer confidence and reduces support inquiries. Consider developing demonstration videos for your website or social media channels to support customer education.

Checking Softness Without Overheating

Step 9: Instruct customers to assess expansion visually before opening the microwave. Properly puffed pieces appear light, airy, with golden-brown coloring.

Step 10: Emphasize a 30-second cooling period before handling due to extreme heat immediately after microwaving. This safety message prevents burn incidents that could generate liability concerns.

Step 11: Provide testing guidelines: use utensils (fork or tongs) to gently press the puffed chew. Texture should resemble cheese puffs or popcorn—light and crispy throughout.

Retail Tip: Create comparison visuals showing unpuffed, properly puffed, and overpuffed chews for packaging or in-store displays. Visual references significantly improve customer outcomes and reduce complaints.

Cooling and Handling After Microwaving

Step 12: Specify the 3-5 minute complete cooling requirement before serving to pets. This prevents mouth burns that could result in negative reviews or complaints.

Step 13: Recommend temperature testing with a finger touch before offering to dogs. Cool or barely warm temperature indicates readiness.

Step 14: Suggest breaking the cooled puffed chew into size-appropriate pieces based on dog size, maintaining supervision during consumption.

Step 15: Provide storage guidance for unused portions: airtight containers, consumed within 3-5 days for optimal quality. This information helps customers maximize value from their purchase.

For distributors developing training programs, role-playing customer interactions around these instructions improves retail staff confidence and creates consistent customer experiences across locations.

Alternative Methods to Microwave Yak Chews

Offering alternative preparation methods expands your customer base to include households without microwaves and customers preferring traditional heating methods. This flexibility increases market penetration and customer satisfaction.

Using Oven or Toaster Instead of Microwave

For customer education materials, include oven-based instructions as an alternative protocol. Preheat to 350°F (180°C), place pieces on parchment-lined baking sheets, and heat for 5-8 minutes with 2-minute check intervals.

The oven method appeals to customers preferring even heating or processing multiple end pieces simultaneously. This batch-processing capability particularly benefits multi-dog households, a growing market segment representing 35% of dog-owning households.

From a retail perspective, highlighting multiple preparation options demonstrates product versatility and addresses diverse customer preferences. Include these alternative methods on packaging or as downloadable resources to maximize customer success.

Hot Water Soaking for Softening Yak Chews

Water soaking represents a gentle alternative for customers concerned about microwave safety or seeking softer textures for senior dogs or puppies. Instruct customers to submerge pieces in 140-160°F water for 5-10 minutes.

This method softens the outer layer without creating the crispy puffed texture, maintaining some chewing resistance. Market this approach specifically for the senior dog and puppy segments, which represent growing demographics in the pet product industry.

For retail staff training, emphasize that soaked chews should be consumed within hours due to increased moisture content. This prevents customer complaints about spoilage while maintaining product safety standards.

Pros and Cons of Each Method

For point-of-sale materials and customer education resources, present this comparative analysis:

- Microwave Method: Fastest option (30-75 seconds), convenient for single pieces, creates light puffy texture. Ideal for customers seeking quick results and dogs preferring crispy treats. Market penetration: suitable for 90% of households with microwaves.

- Oven Method: Longer processing time (5-8 minutes) but accommodates multiple pieces simultaneously. Even heating reduces hot spots. Best for multi-dog households or customers processing several end pieces at once. Requires supervision to prevent burning.

- Hot Water Method: Gentlest approach with very safe outcomes. Creates softened but still firm texture. Specifically targets senior dogs (growing 7% annually), puppies, and dogs with dental sensitivities. Shorter shelf life after treatment requires immediate consumption.

For B2B customers developing marketing materials, segment messaging by customer type. Multi-dog households respond to batch processing efficiency, while senior pet owners prioritize gentle softening options.

Comparing Microwave vs Traditional Softening

From a market positioning perspective, microwave preparation offers the broadest appeal due to speed, convenience, and the dramatic texture transformation customers find satisfying. This method generates the highest social media engagement and positive reviews, contributing to organic marketing value.

Traditional softening through water soaking serves niche segments but represents important market opportunities. Pet specialty retailers can differentiate by offering expert guidance on method selection based on individual dog needs consultative selling that builds customer loyalty and justifies premium pricing.

For distributors developing training curricula, teach retail staff to match preparation methods to customer profiles: busy professionals prefer microwaving, health-conscious pet parents appreciate water soaking options, and multi-pet households value oven batch processing.

Frequently Asked Questions for Yak Chews Customer Service Teams

Equip your customer service teams and retail staff with clear, consistent responses to common inquiries. These standardized answers reduce training time and ensure quality customer interactions across all touchpoints.

how long to heat yak chew in microwave?

To puff a yak chew in the microwave, heat it on high for about 30 to 45 seconds using a microwave-safe plate. The chew will expand and become crunchy as it heats. After microwaving, allow it to cool for 1–2 minutes before giving it to your dog, as it will be very hot. For larger or thicker chews, microwaving in short 10-second intervals helps prevent overheating and ensures even puffing.

What Happens If a Yak Chew Is Microwaved Too Long?

Standard Response: Overheating causes the puffed structure to collapse and become extremely hard, potentially harder than the original chew. Customers may notice burnt odor, dark brown or black spots, and bitter taste. Nutritional value decreases from protein denaturation. Most critically, overheated pieces can develop sharp, brittle edges posing injury risks.

Customer Service Protocol: If customers report overheating issues, first confirm they followed the incremental heating approach (starting with shorter times and adding intervals). Most overheating results from exceeding recommended durations or high-wattage microwaves. Offer replacement pieces for documented issues while reinforcing proper protocols for future use.

Can Puppies Eat Microwaved Yak Chews Safely?

Standard Response: Puppies over four months old with emerging adult teeth can enjoy properly microwaved yak chew pieces broken into appropriate sizes. Puppies under four months should avoid yak chews entirely due to insufficient tooth development. Always recommend veterinary consultation for breed-specific guidance.

Retail Opportunity: This question opens cross-selling opportunities for puppy-specific treat alternatives in your product line. Train staff to recommend age-appropriate products while educating customers about transitioning to yak chews at appropriate developmental stages.

How Often Should You Microwave Yak Chews?

Standard Response: Microwave yak chew pieces only once, at the end of the chew’s life when it becomes too small for safe chewing. This is not a process for repeated use or for softening full-size chews. Each yak chew should provide days or weeks of natural chewing, with microwaving serving as the final step.

Value Messaging: Use this question to reinforce the extended value proposition; customers receive weeks of chewing entertainment plus a final puffed treat, maximizing their investment. This messaging justifies premium pricing and encourages repeat purchases.

how long to microwave yak chew?

To microwave a yak chew, heat it on high for 30 to 45 seconds on a microwave-safe plate until it puffs up and becomes crunchy. Once heated, let the chew cool for 1–2 minutes before giving it to your dog, as it will be very hot. If the yak chew is large or thick, yak chews microwave it in 10-second intervals to avoid overheating and ensure even expansion.

how to microwave yak chew?

To microwave a yak chew safely, first make sure it is a small leftover piece (never a full-sized chew). Rinse the chew under clean water and soak it for 5–10 minutes to add moisture. Place it on a microwave-safe plate and microwave on high for 45 to 60 seconds, depending on the microwave’s power. The yak chew will puff up into a crunchy treat. Let it cool completely before giving it to your dog, as it will be very hot. Once cooled, it becomes a light, crispy snack that is easier to chew and helps reduce choking risk.

how long to soak yak chew?

To soak a yak chew, place it in clean, fresh water for 5 to 10 minutes for small pieces or up to 30 minutes for larger chews. Soaking softens the chew slightly, making it easier and safer for your dog to bite and chew. Always check the chew’s texture; once it becomes pliable but not mushy, it’s ready to serve. This helps prevent choking and makes the chew more enjoyable.

Tips for Storing and Maintaining Softness

Standard Response: Store puffed yak chews in airtight containers at room temperature, away from humidity and direct sunlight. Properly stored puffed pieces maintain texture for 3-5 days. Brief re-crisping in the microwave (10-15 seconds) can restore texture if humidity exposure occurs, though fresh preparation is preferred.

Inventory Management Insight: For retail operations, this storage sensitivity doesn’t affect unpuffed inventory, which maintains quality for 18-24 months in proper warehouse conditions (cool, dry, below 70°F). This exceptional shelf stability reduces shrinkage and supports efficient inventory management.

B2B Implementation Strategies

For Retailers: Develop in-store educational displays featuring microwaving instructions, comparison photos of puffed versus unpuffed chews, and size selection guides. Train staff to demonstrate proper techniques (using sample pieces) during customer interactions. Consider creating store-branded instruction cards as value-added takeaways.

For Distributors: Develop comprehensive training packages including video demonstrations, troubleshooting guides, and customer FAQ sheets for your retail partners. Provide point-of-sale materials highlighting the microwaving feature as a unique value proposition. Consider offering staff training webinars to ensure consistent product knowledge across your retail network.

For Private Label Partners: Incorporate detailed microwaving instructions directly into packaging design. Include QR codes linking to video demonstrations. Develop strong safety messaging that protects brand reputation while emphasizing the extended value proposition.

For E-commerce Operations: Create robust product page content including video demonstrations, detailed FAQs, and customer testimonials specifically addressing the microwaving process. Consider including printed instruction cards with shipments to reduce support inquiries and increase customer satisfaction.

Maximizing Yak Chew Profitability Through Customer Education

Understanding and effectively communicating proper microwaving protocols transforms yak chews from single-use products into extended-value offerings. This knowledge enables your business to command premium pricing, reduce returns, minimize customer service inquiries, and build customer loyalty through expert guidance.

By equipping your team with comprehensive product knowledge and standardized customer education resources, you position your business as the trusted authority in natural pet treats. This expertise differentiates you from competitors and creates lasting customer relationships that drive repeat purchases and positive referrals.