Did you know that up to 30% of natural dog treats spoil within a few months if stored the wrong way? Yak/cow milk chews, also called chhurpi or Himalayan Dog Chew, are made from Himalayan yak and cow milk. They are long-lasting, nutritious, and preservative-free. This means proper storage directly affects their freshness and safety. Whether you’re a pet store owner, distributor, or simply stocking up on YforYak treats, knowing how to store them correctly is essential.

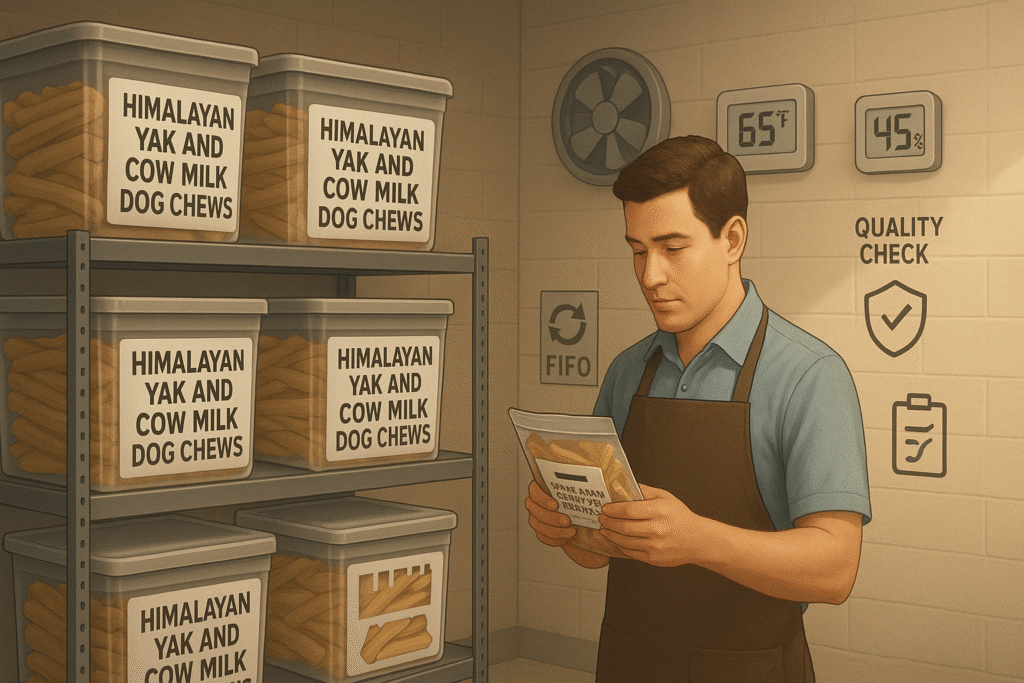

Keeping yak and cow milk chews safe takes more than neat shelving. It depends on controlling temperature, humidity, packaging, and handling. The Yak/Cow Milk Chews Storage Guide from YforYak gives retailers, warehouse managers, and sellers a clear plan. It helps extend shelf life, prevent spoilage, stop pests, and keep every batch traceable.

The guide covers temperature and humidity ranges, packaging methods, receiving and rotation steps (FIFO), pest control, quarantine, and ready-to-use checklists. By following these, you’ll reduce returns, maintain product quality, protect pet health, and improve storage and shipping efficiency.

In the end, you’ll know exactly how to keep yak/cow milk chews fresh, avoid common spoilage problems, and ensure these chews stay safe for as long as possible.

How sensitive are yak/cow milk chews to temperature, humidity, light, and airflow?

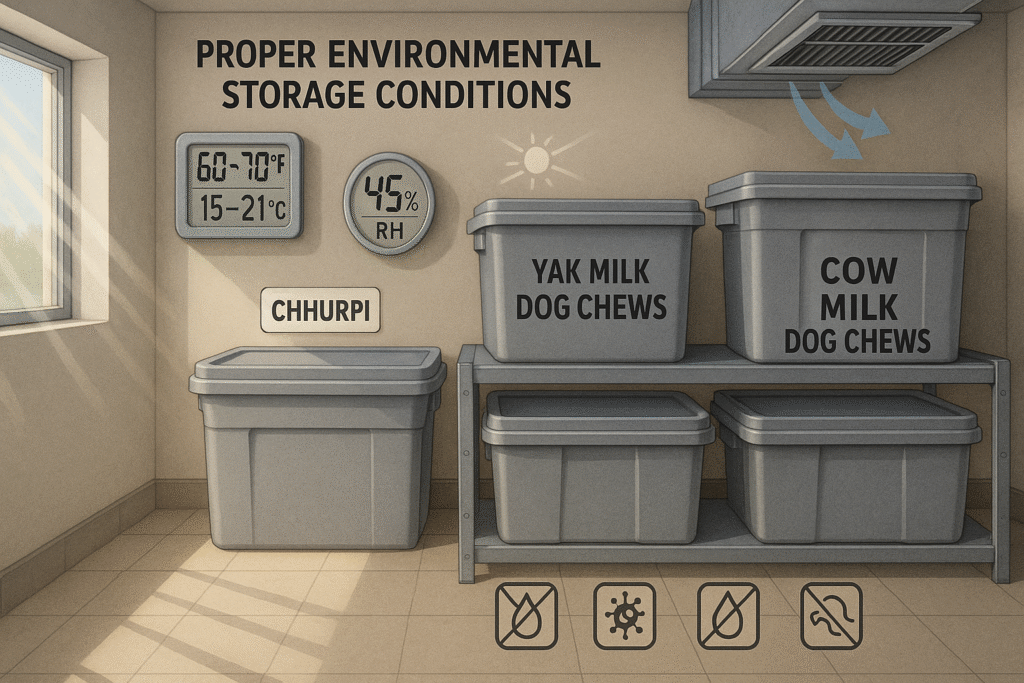

- Temperature: Chews should be stored at a stable temperature between 60–70°F (15–21°C) to maintain their texture and flavor. Higher temperatures may cause oil separation or softening, while temperatures below 50°F (10°C) can make them brittle and more likely to crack.

- Humidity: Maintain relative humidity between 40–50% to preserve the quality of yak and cow milk chews. High humidity can cause moisture absorption, leading to mold growth and a reduced shelf life. Low humidity may overdry the chews, making them too hard, potentially harming a dog’s teeth, or diminishing their flavor. Consistent, moderate humidity helps prevent both mold and excessive drying.

- Light Exposure: Exposure to direct sunlight or UV light can degrade natural food products like yak milk chews. UV rays may break down nutrients, fade flavor, and oxidize fats over time. Prolonged exposure to indoor fluorescent lighting may also cause minor effects. To prevent light-related damage and heat buildup, store chews in the dark or in opaque packaging.

- Airflow and Odors: Store chews in sealed containers to prevent staleness from air exposure. While the storage room should have good ventilation to reduce moisture buildup, the chews themselves should not be left out in the open air. Keep them away from strong-smelling substances like chemicals or spices, as their dairy content can absorb surrounding odors over time.

Condensation control tip: After doors open in hot/humid weather, allow a gradual return to setpoints (don’t blast cooling) to avoid condensation inside packaging.

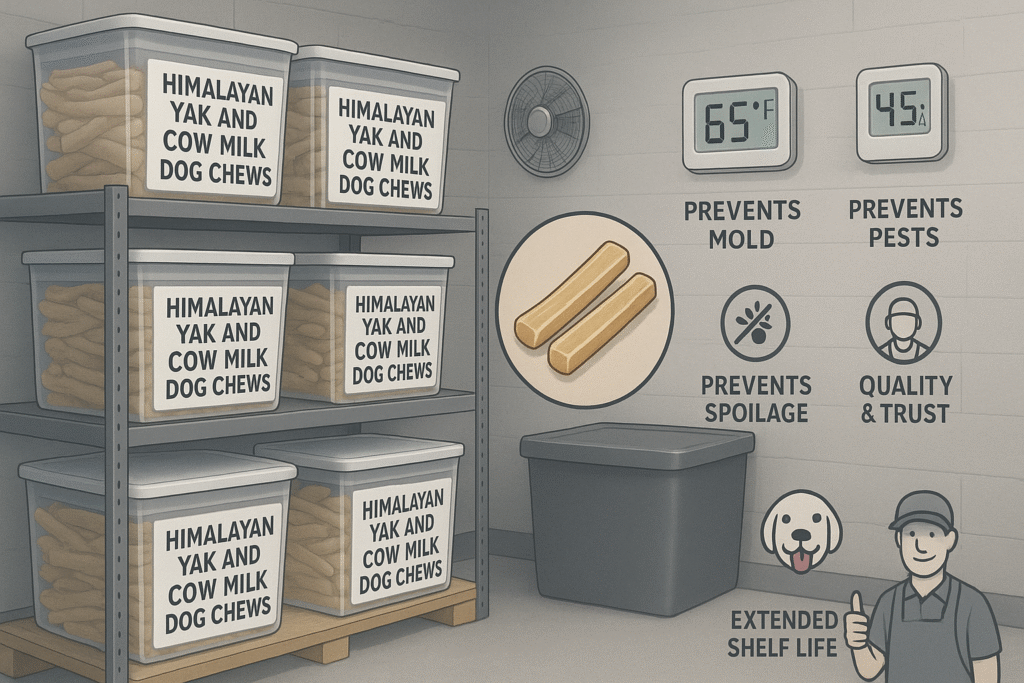

Why does proper storage of yak/cow milk chews matter?

Yak and cow milk chews are dense, all-natural cheese treats made without preservatives. Although low in moisture, they remain sensitive to humidity, heat, and pests. Improper storage can lead to mold, unpleasant odors, texture changes, or pest contamination issues that may result in product returns, customer complaints, or risks to pet health. Storing them correctly preserves quality, maintains nutritional value, and protects your brand. Proper storage is essential to:

- Prevent spoilage and Mold: Yak and cow milk chews are dairy-based and can spoil or develop mold if stored in high humidity or unsuitable conditions. Moldy or rancid chews pose health risks to pets and result in product loss. A cool, dry storage environment helps prevent spoilage and protects both product quality and pet safety.

- Maintain freshness and nutrition: Proper storage preserves the texture, flavor, and protein content of yak and cow milk chews. Excess heat or humidity can degrade nutrients, as noted by the FDA, and may cause the chews to become either overly hard or too soft. Over-drying or cold conditions make them brittle, while warmth and humidity lead to a sticky, degraded texture, both of which reduce their shelf life and long-lasting quality.

- Extend shelf life: Unopened yak and cow milk chews can remain usable for extended periods when stored properly. Some manufacturers report shelf lives of up to 5 years in sealed packaging, while we note 2 years of stability. With correct storage conditions, chews typically stay fresh and safe for many months or longer.

- Ensure safety and compliance: Avoid Pest Contamination. Without proper storage, pests such as rodents or insects can contaminate chews. Using sealed containers and maintaining a clean environment protects inventory from infestation. Safe storage also ensures compliance with pet food safety standards. The FDA recommends keeping treats in their original, labeled containers to maintain traceability. By following these practices, retailers can avoid recalls, maintain customer trust, and ensure that lot numbers and best-by dates remain easy to access.

- Financial Savings & Customer Trust: Each spoiled chew represents a financial loss. Proper storage extends product life, reducing waste and minimizing losses from unsellable inventory. Consistently fresh, high-quality chews also build customer satisfaction and strengthen your brand’s reputation.

Treating yak and cow milk chews as moisture-sensitive food products, rather than standard dog treats, helps preserve quality and safeguard pet health.

How do all-natural composition and shelf-stability affect storage?

- Simple Ingredients: Yak/cow milk chews (often branded as Himalayan dog chews) are made from just milk (yak and/or cow), plus a bit of lime juice and salt. They’re boiled, pressed, and dried into hard cheese-like treats. Because they’re natural with no artificial preservatives, their longevity depends heavily on how you store them.

- Dried Dairy Product: Think of these chews as a hardened dairy product – similar to a very hard cheese. They have no moisture area, which gives them a long shelf life, but only if kept dry. If they absorb moisture from the air, that can lead to fungus or bacterial growth over time.

- High Protein, Low Fat: These chews are high in protein and low in fat. While that makes them healthy for dogs, it also means they can become rancid or lose nutritional value if exposed to heat, light, or air for extended periods. Proper storage preserves their protein content and flavor.

- No Strong Odors (Unless Spoiled): Fresh yak milk chews have very little odor. If you notice a strong sour or rotten smell, it’s a sign something’s wrong – either they got damp or are past their prime. Storing them correctly helps ensure they remain virtually odorless and appetizing to dogs.

What are the optimal warehouse storage conditions for yak/cow milk chews?

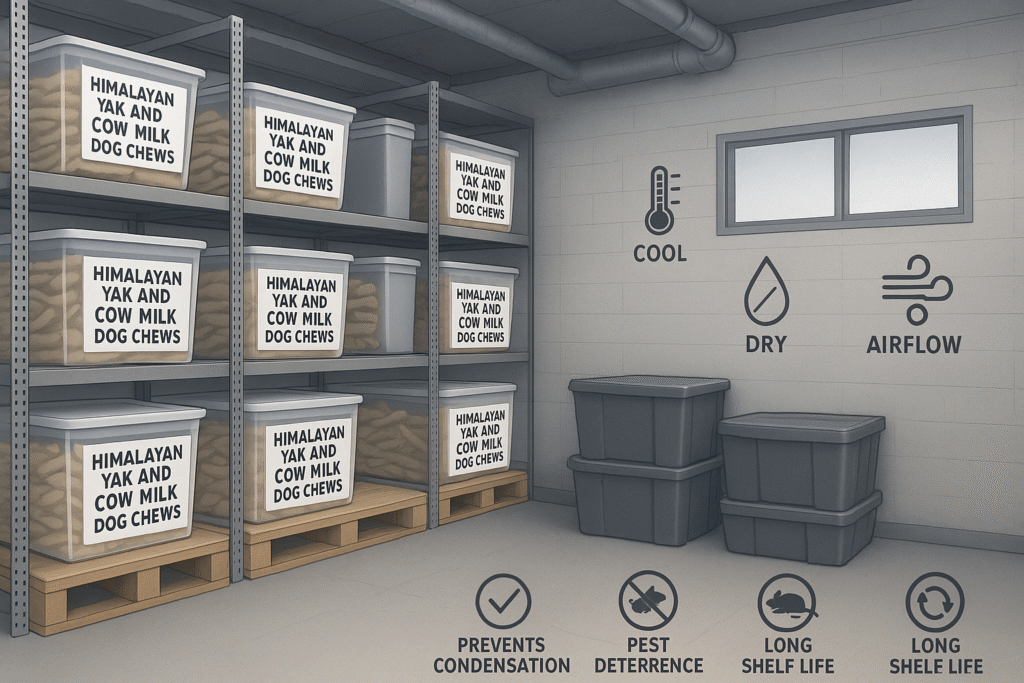

To maximize shelf life, recreate the chews’ “happy place” in your warehouse: cool, dry, and dark. Key conditions to maintain:

- Consistent Cool Temperature: Aim for a storage temperature around 65°F (18°C). Warehouse areas should ideally stay in the 60–70°F range year-round. Avoid placing chews near heat sources or in direct sunlight by a window. If your climate is hot, consider a climate-controlled storage room or use fans/HVAC to keep temperatures stable. Avoid fluctuations – drastic swings from hot days to cool nights can create condensation inside packaging.

- Moderate Humidity: Keep relative humidity around 45%. Use a hygrometer (humidity monitor) in the storage area. In a humid climate or during summer months, a dehumidifier might be necessary to stay in the safe range. In very dry conditions (winter or arid climates), ensure the chews are in sealed packaging so they don’t desiccate further (you generally won’t need to add humidity, as dryness is less dangerous than dampness for these treats).

- Air Circulation: Ensure the storage area is well-ventilated. Good airflow prevents pockets of moisture-laden air. Avoid sealing chews in an airtight room – while the containers should be airtight, the room should have no direct airflow or occasional air exchange. Ventilation and perhaps an oscillating fan can help keep conditions uniform.

- No Direct Light: Store chews away from sunlight. If your warehouse has windows, use curtains, UV-blocking film, or simply keep the chews in a shaded corner. Using opaque bins or boxes adds a layer of light protection (and as a bonus, helps keep the temperature steady inside).

- Off the Floor: Standard good warehousing practice – keep all pet food products off the concrete floor, which can sweat moisture. Use pallets or shelves. This keeps the chews dry and also deters pests (it’s easier to spot and stop pests on shelving than hidden under pallets on the ground).

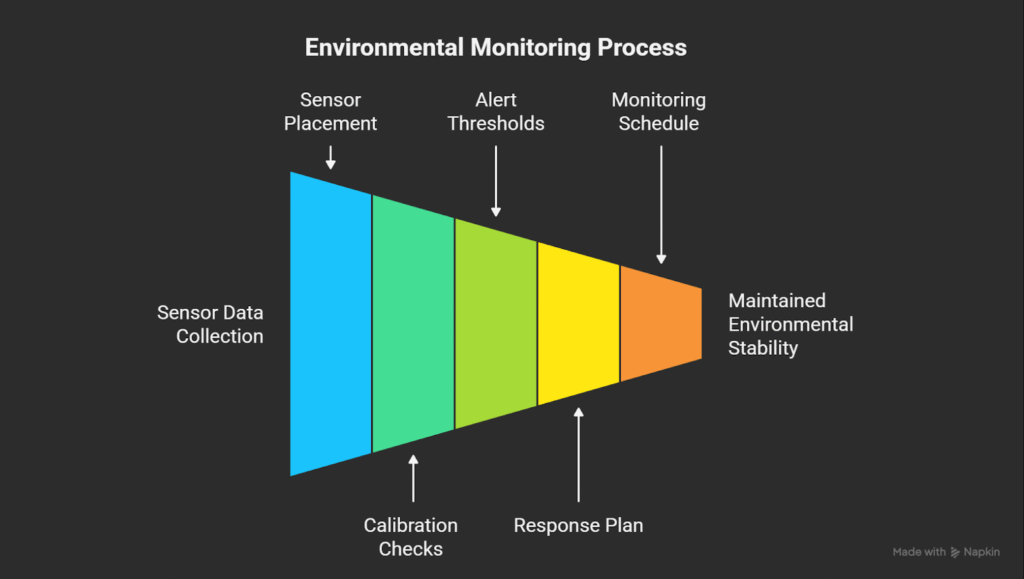

Which sensors and alerts should you use, and where should you place them?

Devices: Use data loggers to track environmental history. Use digital hygrometers/thermometers for real-time spot checks.

Sensor Placement: Place sensors at eye level on middle racks, away from doors, windows, and vents. Install one sensor per zone: top level, middle section, and aisle end.

Calibration: Check sensor calibration every quarter according to vendor instructions. Replace batteries before they weaken to ensure uninterrupted operation.

Alert Thresholds:

- Temperature: Trigger an alert if the temperature drops below 59°F (15°C) or rises above 70°F (21°C) for more than 30 minutes.

- Relative Humidity: Trigger an alert if RH drops below 35% or rises above 55% for more than 30 minutes.

Response Plan:

- Investigate: Confirm the issue by checking sensor location, timestamp, and any nearby activity or event.

- Correct: Adjust HVAC settings, add dehumidifiers, block sunlight, or move affected pallets.

- Document: Re-log the condition and add a note to the condition log.

Monitoring Schedule:

- Perform a quick visual check of all sensors daily.

- Export data weekly and attach logger graphs to the quality control file.

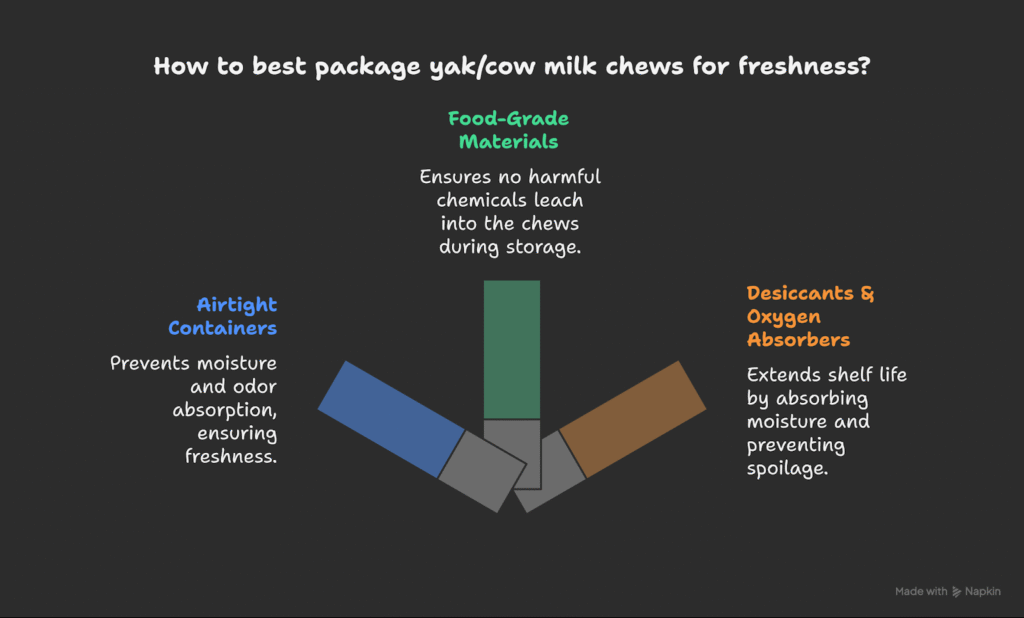

What packaging and container best practices keep yak/cow milk chews fresh?

How you package the chews for storage is just as important as the room conditions. Follow these packaging tips to lock in freshness:

- Airtight Containers: Always store yak/cow milk chews in airtight packaging. Resealable heavy-duty plastic bags, plastic airtight bins with gasket seals, or vacuum-sealed packs are excellent choices. Removing or limiting exposure to air keeps moisture out and also prevents the chews from absorbing odors or humidity from the room.

- Food-Grade Materials: Ensure any container or bag is food-grade. Chews may be in storage for many months, and you don’t want any harmful chemicals leaching in. Stick to food-safe plastics or glass. (Most commercial packaging that chews come in from manufacturers is already food-safe.)

- Desiccants & oxygen absorbers: When storing a large volume of chews together (big bags or bins of them), consider adding silica gel packets or oxygen absorbers into the container. Silica gel will absorb any residual moisture in the air inside the container, and oxygen absorbers can help prevent oxidative spoilage. This can significantly extend shelf life, especially in less-than-ideal ambient conditions. (Just be sure to keep those packets out of reach of pets when you eventually handle the chews!)

How much desiccant do you need per container volume?

Use ~1–2 g silica gel per liter of headspace (verify vendor spec). Double during monsoon/high-humidity periods. Replace when the indicator turns color.

- Opaque or Dark Packaging: As mentioned, light can degrade the product, so if possible, use packaging that is not transparent. For example, store chews in a solid color bin or Mylar bags so that light can’t penetrate. If you use clear bags for retail display later, at least keep those in a dark box while in warehouse storage.

- Secure Sealing: After each time you open a container or bag to take some chews out, reseal it tightly. If a bag doesn’t reseal, use clips or transfer the contents to a container that can seal. The less time chews spend exposed to open air, the better.

- Label and Date Batches: On each container, use a label to note the batch/date (e.g., when the chews were produced or received). This will help immensely with rotation (FIFO) and quality control. It’s hard to tell chews apart by looks, so good labeling prevents older stock from being forgotten.

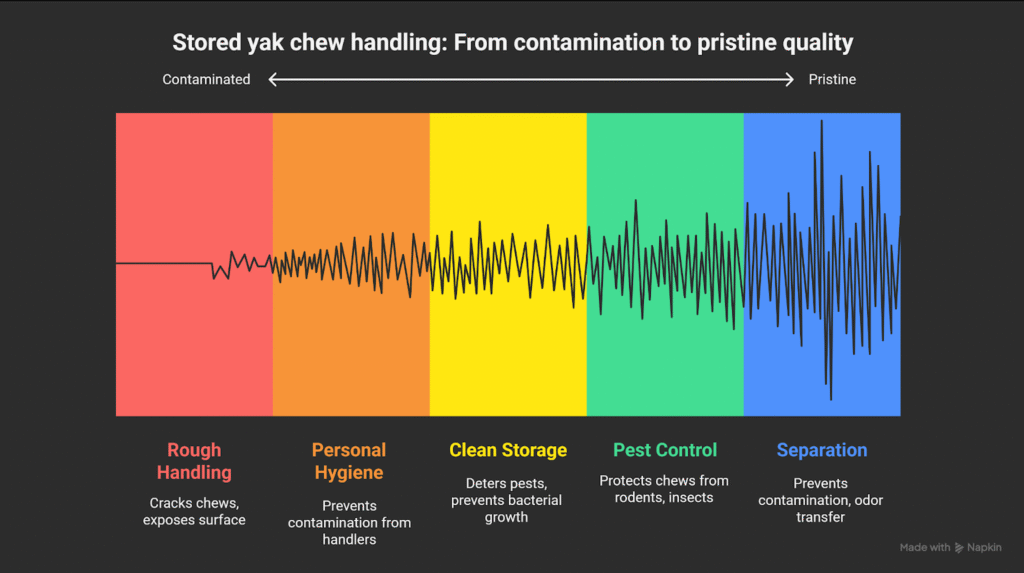

How should handling, hygiene, and pest control be managed for stored yak/cow milk chews?

Even with perfect climate and packaging, human handling and warehouse hygiene can make or break your storage success. Keep these best practices in mind:

- Gentle Handling: Yak and cow milk chews are hard, but they can still crack or break if roughly handled (for instance, dropping a box of them could shatter some into smaller pieces). Train your staff to handle boxes or bags of chews with care. When transferring chews (say, from bulk packaging to smaller packs), do so over a clean surface and avoid unnecessary crushing or pressure. Broken pieces are not only harder to sell but also might expose more surface area to air, hastening spoilage.

- Personal Hygiene: Anyone handling the chews (during repackaging or quality checks) should have clean hands or wear disposable gloves. This prevents oils, moisture, or germs from our hands from contaminating the treats. It’s a food product (for pets), so treat it with similar care as you would human food in a storage setting.

- Clean Storage Area: Maintain a regular cleaning schedule for your warehouse or storeroom. Sweep up crumbs or fragments of treats promptly – leftover food debris can attract pests. Wipe down surfaces to ensure there’s no sticky residue or spillage that could harbor bacteria or mold. Keeping the area clean also makes it easier to inspect and ensures there aren’t hiding spots for pests.

- Pest Control Measures: Proactively protect the chews from rodents and insects. Use sealed containers (as mentioned) so pests can’t chew through to the product. Additionally, employ pest control tactics: set out insect traps or bait stations around the perimeter (in areas pets can’t access, if it’s a retail storeroom), use ultrasonic pest repellents if effective, and have a plan for regular pest inspections. Ensure any warehouse doors or windows have proper seals – a simple gap under a door can invite mice or bugs.

- Separate from Non-Food Items: If possible, store yak/cow milk chews in an area dedicated to pet products or treats. Keep any chemicals, cleaning supplies, or strongly scented non-food items well away. This avoids any accidental contamination (or odor transfer – e.g., you don’t want your chews smelling like detergent or motor oil because they were stored next to them).

- Training & Protocols: Implement standard operating procedures for anyone who handles the inventory. This might include things like: “wash hands before touching product,” “don’t place chews directly on the floor,” “immediately reseal packages after opening,” etc. When everyone follows the same protocols, the risk of contamination drops and product quality stays high.

How should warehouse layout and palletization be set to protect these chews?

Airflow Lanes: Keep aisles clear to promote airflow. Eliminate dead-end corners that trap heat or humidity.

Standoffs from Walls: Maintain a 10–15 cm gap between pallets and walls to allow airflow and enable visual inspection.

Rack Positioning: Do not store products on top racks exposed to roof heat or skylight radiation. These zones are more prone to temperature spikes.

Light Management: Cover windows with shades or UV-filtering film. Store light-sensitive products in low-light or fully dark areas.

Pallet and Wrap Use: Place products on pallets to prevent floor contact. Use opaque wraps to block light exposure or breathable wraps when airflow is the priority. Choose based on storage zone conditions.

How should storage practices adjust across climates and seasons?

High Humidity / Monsoon Conditions: Install vestibules or air curtains to limit moisture entry. Increase the use of dehumidifiers. Use two layers or units of desiccant per pallet. Minimize how long doors remain open during loading or inspection.

Cold or Arid Conditions: Prevent product brittleness by avoiding excessive dryness. Insulate any walls exposed to outside cold. Maintain indoor temperatures above 50°F (10°C) to prevent quality degradation.

Seasonal Prep Checklist:

- Conduct a full seal audit before the monsoon season.

- Implement a humidity control plan before winter begins.

- Brief seasonal staff on updated handling protocols and adjust quality control routines to match the environmental risks of the season.

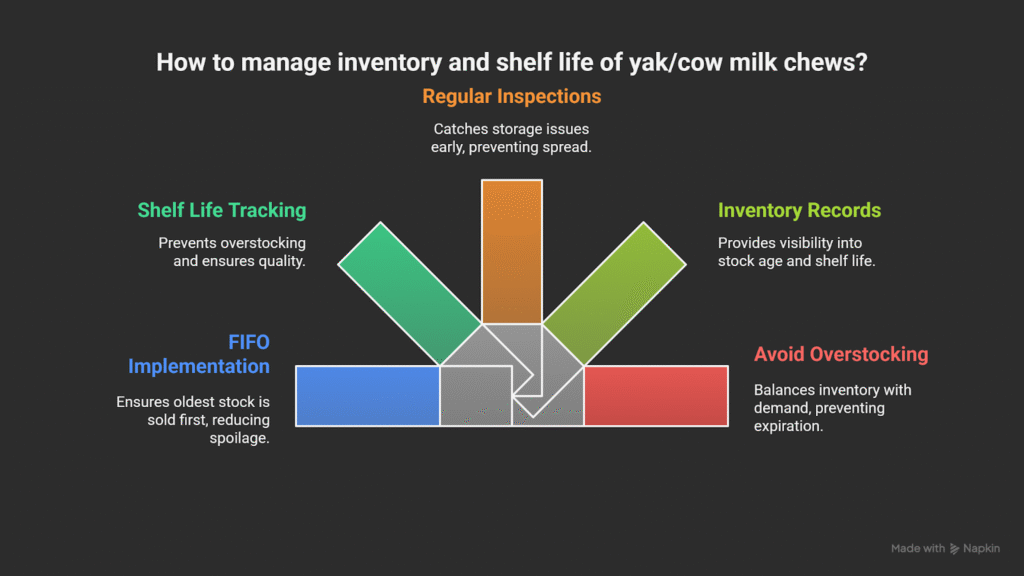

How should inventory and shelf life be managed for yak/cow milk chews?

Storing the chews correctly goes hand-in-hand with smart inventory management. You want to ensure first in, first out, and keep an eye on how long products have been stored. Here’s how:

- FIFO (First-In, First-Out): Always organize your stock so that the oldest batches of chews (the ones that arrived or were produced first) will be shipped out or sold first. When new stock comes in, place it behind or beneath older stock. This way, you naturally rotate inventory. FIFO prevents a situation where a box of chews sits forgotten in a corner for two years. It’s one of the simplest ways to reduce spoilage.

- Track Shelf Life: Yak and cow milk chews generally have a long shelf life – often 12 to 24 months at high quality but they’re not infinite. Check the manufacturer’s guidelines if available (some premium chews, like those from YforYak, may list a best-by date). In ideal conditions, you might even get up to 2 years of shelf life with minimal quality loss. However, in suboptimal conditions, that can drop to under 6 months. It’s useful to know these benchmarks so you don’t overstock beyond what you can sell in time.

- Regular Inspections: Don’t just set and forget your chews. Do a quick inventory inspection monthly (or at least every couple of months). Randomly open a container or two to look at the chews: ensure no mold, no pest droppings, and that the texture seems right. This helps catch any storage issues early. If you find a problem (e.g., one container has some moldy pieces), you can address it. Perhaps the area was too humid, or that batch was flawed and prevented it from spreading to other stock.

- Inventory Records: Maintain a log or digital system noting when each batch arrived and its expected shelf life. Modern inventory software can alert you when a batch is nearing its best-by date so you can prioritize its sale or use. Even a simple spreadsheet can do the job for a small operation. The key is to have visibility into how old each lot of chews is.

- Avoid Overstocking: Especially for retailers, it might be tempting to buy yak chews in bulk for a discount. But if you overstock beyond what you can realistically sell in a year, you risk them sitting too long. Balance your inventory levels with demand. It’s better to reorder more frequently than to have products expiring on the shelf.

- Shelf Life by Conditions: Ideal storage conditions can extend shelf life significantly. To illustrate, here is a rough comparison of shelf life under different conditions.

When should FEFO override FIFO to maintain optimal freshness?

Use FEFO (First-Expiry, First-Out) when inventory includes mixed best-by dates or when products remain in storage for extended periods. Use FIFO (First-In, First-Out) when batch dates are uniform and dwell times are short.

What shelf life should you expect under different conditions?

Shelf life depends directly on how well temperature, humidity, and light are managed. Better control leads to longer-lasting product quality. The table below shows the estimated shelf life for yak and cow milk chews under different storage environments.

| Storage Condition | Expected Shelf Life | Quality Retention |

| Optimal (60-70°F, 40-50% RH, dark) | 18–24 months | ~95–100% (near original quality) |

| Cool & Controlled (room temp ~68°F, modest humidity) | 12–18 months | ~85–90% (minor staleness possible) |

| High Humidity Environment (e.g. >60% RH) | 6–12 months | ~60–75% (risk of some mold or softness) |

| Poor Conditions (hot >80°F or very humid, exposure to light) | 3–6 months | ~40–60% (likely quality loss, possible spoilage) |

How do you troubleshoot quality issues and run QC checks effectively?

| Symptom | Likely Cause | Immediate Action | Preventive Fix |

| Surface white bloom | RH cycling / condensation | Quarantine; inspect for mold | Stabilize RH; add/refresh desiccants |

| Oil “sweating” | Heat exposure | Move to cool zone; sample check | Shade/insulate; keep <70°F (21°C) |

| Soft/chewy texture | High humidity | Discard if contamination risk | Increase dehumidification; improve sealing |

| Brittle/cracking | Over-drying / cold | Adjust setpoints; re-pack | Avoid <50°F (10°C); maintain airtight packs |

| Off odors | Oxidation/contamination | Discard batch | Opaque packs; improve hygiene & rotation |

Recall isolation drill: Bag/tag suspect lots, segregate in a quarantine zone, notify stakeholders, document findings, and resume only after root-cause fix is verified.

What regulatory compliance and safety guidelines apply to storing yak/cow milk chews?

Storing pet food and treats like yak/cow milk chews isn’t just about quality – it’s also about safety and compliance. Here are some guidelines to ensure your storage meets industry standards and regulations:

- Follow Pet Food Storage Regulations: In many regions (for example, the U.S.), facilities that store pet edibles should adhere to similar principles as human food storage. The FDA has Good Manufacturing Practices (GMPs) that extend to warehousing. This means keeping the area pest-free, adequately dry, and preventing contamination. Familiarize yourself with any local or national regulations for pet treat storage – often provided by organizations like AAFCO (Association of American Feed Control Officials) or your local food safety authority.

- Proper Documentation: Keep records of your storage conditions and procedures. For instance, maintain logs for temperature and humidity (especially if you’re storing a large volume commercially). Document cleaning schedules, pest control measures, and any employee training. Good record-keeping not only helps in case of a safety audit but also ensures consistency in your operations.

- Batch Traceability: As part of compliance and quality control, use batch numbers (which you’ve labeled on each container) to trace products. If there’s ever an issue or recall with a particular batch of chews, you’ll want to quickly identify and isolate it. Keep a log of batches received and where they are stored.

- Storage Area Standards: Ensure the storage area itself meets any required standards: for example, no direct contact with the floor or walls (use pallets/shelves), adequate lighting (for workers to inspect products, even though products themselves should be shielded from light), and restricted access to authorized personnel (to prevent any accidental contamination or tampering).

- Safety Data Sheets (SDS): If you use any cleaning chemicals in the storage area, keep SDS documents on hand and away from the products. Also, while yak chews are natural, if any additive or preservative is used by certain brands, having product spec sheets can be useful. Employees should know that while these are dog treats, they should be handled and stored as carefully as any food item.

- Regular Audits: Periodically review your storage practices against guidelines. It could be an internal audit or part of a certification (some pet food companies opt for certifications like HACCP for their processes). Being proactive about safety and compliance will protect your business and ensure the chews that reach customers are absolutely safe.

How do you maintain freshness and safety during transport and last-mile storage?

- Pre-dispatch checks: Confirm internal pack temp/RH near warehouse setpoints; verify seals intact.

- In transit: Shade/insulate loads; avoid sun-baked dwell times; minimize door opens.

- Receiver acceptance checklist: Check temp/RH, seals, damage, odors; reject if parameters fail.

- Retail backroom: Keep off floors, away from windows/HVAC vents; maintain cool, moderate RH; reseal opened cartons promptly.

How can you improve sustainability and control storage costs at once?

- Energy-smart setpoints: Avoid over-cooling; use night setbacks and door discipline.

- Packaging: Prefer opaque/recyclable materials; reuse durable bins.

- Operations: Consolidate partials to reduce headspace; monitor kWh per pallet as an efficiency KPI; fix leaky seals/gaps first.

What storage practices does YforYak specifically recommend for best results?

- Target ranges: 62–68°F (17–20°C) and 40–50% RH with minimal daily swing.

- Packaging: Opaque, airtight primary packs; add silica gel for bulk bins; keep retail clear bags inside dark cartons until display.

- Labeling: LOT / Date of Manufacture (DOM) / Best-By (BB) on every case and bin.

- QC cadence: Monthly sampling (look/smell/feel), plus logger graph review.

- Support: For COAs/spec sheets or storage questions, contact YforYak support.

What is the best way to store yak/cow milk chews to keep them fresh?

The best way is to store yak and cow milk chews in a cool, dry place away from sunlight. Aim for around 50–70°F (10–21°C) and moderate humidity (~40–50%). Keep them in airtight food-grade containers or bags. This ensures they stay hard, clean, and tasty for as long as possible.

How can I prevent moisture from affecting my stored chews?

Moisture is the enemy of these chews. To combat it, use airtight containers with a good seal so humid air can’t get in. Adding a silica gel desiccant pack inside the container will absorb excess moisture. Also, monitor your storage room’s humidity. If it’s above ~60%, use a dehumidifier. And never store the chews near sources of moisture or in a damp basement.

What type of packaging is best for yak and cow milk chews?

Airtight, opaque packaging is ideal. For example, thick resealable plastic bags (like the ones YforYak chews come in) or screw-top plastic jars work great. The packaging should be food-safe and snug – squeeze out extra air if using bags. Opaque or dark packaging is better than clear, because it shields the chews from light. Always make sure the package is truly sealed after each use.

How often should I inspect the chews in storage for spoilage?

It’s wise to check on your stored chews about once a week, or at least a couple of times a month. Especially in the first few weeks of storage or during humid seasons. When you inspect, look for any white or green fuzzy spots (mold) on the chews, sniff for any sour or off odors, and feel if any pieces have gotten unusually soft or slimy. Early detection of a problem can save the rest of your stock from contamination.

Can I store yak/cow milk chews together with other pet products?

Try to store them separately if possible. Yak/cow milk chews can absorb odors, so you wouldn’t want them next to, say, strongly scented pet treats or chemicals. Also, separating them prevents any cross-contamination (for example, if you also store rawhide or pig ears, which might carry different bacteria). If space is limited and they must share an area, ensure all products are well-sealed and the area is clean. But the safest bet is giving these chews their own dedicated shelf or bin.

What are the benefits of using FIFO rotation for these chews?

FIFO (First-In, First-Out) ensures that the oldest chews (first in) get used or sold first (first out). The benefit is that no single batch sits around too long. This minimizes the chances of any product exceeding its shelf life in storage. For a product with a long but finite shelf life, like yak chews, FIFO means customers are more likely to get a fresher product, and you’re less likely to find an expired batch in the back of the warehouse. It’s a simple system that reduces waste and keeps inventory moving.

How can I manage inventory levels effectively for my chew products?

Effective inventory management comes down to tracking and planning. Use an inventory management software or even a spreadsheet to log incoming batches (with dates and quantities). Set reminders for when it’s time to re-order based on how quickly you’re selling them. Keep an eye on seasonal trends – for instance, if chews sell faster in winter, stock a bit more ahead of that time, but not so much that they’ll sit unsold through next summer. Regularly do a physical count to reconcile with your records. By knowing exactly what you have and how fast it’s moving, you can avoid both overstocking and running out.

Are there any regulatory guidelines for storing pet treats like yak milk chews?

Yes, in many places, pet treats are regulated almost like human food. For example, the FDA requires that pet food (which includes treats) be stored in sanitary conditions. This means your storage area should protect the chews from pests, extreme conditions, and contamination. You should also keep proper records (like lot numbers, as mentioned earlier) in case of recalls or inspections. AAFCO provides model guidelines. one rule of thumb is to store pet food off the ground and away from walls, maintain clean facilities, and control pests. If you’re ever unsure, check the local feed/food regulations or consult with the manufacturer (they often have storage recommendations to meet their quality standards).

How can I prevent pests from infesting stored chews?

To prevent pests, focus on cleanliness and barriers. Clean up any food debris that could attract bugs or rodents. Use sealed containers that pests can’t chew through (heavy plastic or metal bins can stop rodents better than cardboard). Set up preventative measures like sticky traps for insects or bait stations for rodents around the storage area (but not where they could contaminate your chews). Also, inspect the area regularly – look for signs like droppings or gnaw marks. If you see any, take action immediately (you might need to involve pest control professionals for a serious infestation). By being proactive, you can usually keep your warehouse pest-free.

Are there eco-friendly packaging options for yak/cow milk chews storage?

Absolutely. Many pet businesses and consumers appreciate eco-friendly practices. You can use biodegradable or compostable bags made from plant-based plastics for packaging the chews. Another option is sturdy, recyclable containers (like certain recyclable #5 plastic tubs or even metal tins) that can be reused by customers. Just make sure any alternative packaging still keeps the chews dry and protected. Some brands offer refills in bulk to stores, which then use their own sustainable containers for display. If you go eco-friendly, let your customers know – it can be a great selling point that your packaging is earth-conscious while still maintaining product quality.

What are the key takeaways and next steps for storing yak/cow milk chews?

Storing yak and cow milk chews properly is the key to preserving their freshness, safety, and value. By maintaining the right temperature and humidity, using airtight packaging, keeping a clean and pest-free environment, and staying on top of inventory rotation, you’ll ensure these natural dog treats remain as fresh and delicious as the day they were made. For retailers and warehouse managers, these best practices mean longer shelf life, less product loss, and happier customers (and pups!). Remember, a little effort in storage goes a long way in guaranteeing quality.

Ready to put these storage tips into action? Start applying them in your warehouse today to protect your investment. For any questions or to stock up on premium Himalayan yak chews made with care by YforYak, contact us. We’re here to support your success and keep tails wagging!