How We Manufacture Himalayan Yak Chews: Our Complete Process

At our facility, we’ve spent years perfecting the art and science of manufacturing authentic Himalayan yak chews. While many companies offer simple explanations of traditional methods, we believe pet owners deserve complete transparency about how we transform ancient chhurpi cheese-making techniques into the safe, durable chews their dogs love.

We start every batch with the same question our Himalayan partners have asked for centuries: how do we preserve milk’s nutrition while creating something dogs can safely enjoy for hours? Our answer combines traditional wisdom with modern food safety science, ensuring every chew meets both our quality standards and your dog’s needs.

This is the complete story of how we manufacture yak chews from sourcing milk in remote Himalayan valleys to the moment a finished chew reaches your dog’s bowl.

Our Complete Process Overview

Milk sourcing & intake testing

We verify quality and document sources

Fat and solids standardization

We prepare consistent raw materials

Controlled heat treatment

We use validated temperature programs

Acidification and coagulation

We add cultures, Lime juice, and salt

Draining and pressing

We remove whey over 24 hours

Drying and smoking

We process to our water activity targets

Conditioning and aging

We equalize moisture and verify quality

Finishing and treatment

We prepare safe, properly sized chews

Protective packaging

We seal in barrier films with moisture control

What We're Actually Making: Understanding Chhurpi

The Ancient Foundation We Build Upon

We don’t just make dog chews, we make chhurpi, the centuries-old Himalayan hard cheese that has sustained high-altitude communities across Nepal, Tibet, and Bhutan. Our process honors this traditional food while adapting it specifically for dogs’ dietary and safety needs.

Traditional chhurpi creation involves transforming yak, chauri (yak-cattle hybrid), cow, or buffalo milk into rock-hard cheese through careful pressing and drying. We’ve learned that this ancient matrix characterized by extremely low moisture, dense casein proteins, and sun or smoke-drying creates exactly what dogs need:

- Natural digestibility from fermentation and protein breakdown

- Perfect hardness for extended, safe chewing

- Long-term stability without artificial preservatives

Why We Adapted Human Food for Dogs?

We recognized that chhurpi’s natural properties made it ideal for canine nutrition. The same hardness that allowed Himalayan herders to gnaw on chhurpi during long mountain journeys provides dogs with hours of satisfying chewing activity. More importantly, we saw how our manufacturing could support the Himalayan communities who created this food centuries before we existed.

Our Complete Manufacturing Process: Every Step We Take

Step 1: How We Source and Accept Raw Milk

Our Approach to Milk Sourcing

We’ve built direct relationships with high-altitude cooperatives that provide yak / chauri milk, while maintaining partnerships with lower-altitude farms for bovine sources when needed. We’re transparent about this blend because Nepal’s yak milk supply is naturally seasonal and limited, forcing us to choose between year-round availability or authentic sourcing. We choose both by working with multiple traditional producers.

Supporting Our Source Communities

Every purchase we make directly benefits Himalayan herders and cooperatives. We maintain complete traceability back to specific producer groups, not just for quality control but to ensure our business genuinely supports these communities’ economic development.

Our Quality Control at Intake

We test every milk delivery following both FEDIAF (European Pet Food Industry Federation) and FDA guidelines:

- Temperature verification upon arrival using calibrated thermometers

- Complete sensory evaluation by trained technicians

- Chemistry analysis including acidity and composition testing

- Antibiotic and inhibitor screening using validated test methods

- Comprehensive adulteration checks

- Full documentation for complete batch traceability

We reject any milk that doesn’t meet our specifications, regardless of supply pressures.

Step 2: How We Standardize Fat and Solids

We learned from traditional chhurpi makers that low-fat milk produces harder, more stable cheese. Following this wisdom, we separate cream and carefully standardize our solids-non-fat (SNF) content to ensure every batch produces consistent curd firmness and predictable drying performance.

This standardization step is where we bridge tradition and modern manufacturing. We achieve the consistency our customers expect while maintaining the authentic profile that makes chhurpi special.

Step 3: Our Controlled Heat Treatment Process

We use two validated approaches, choosing the method based on each batch’s requirements:

- Traditional High-Heat Method: We follow rural production practices by bringing milk to a controlled boil, carefully managing temperature to denature proteins and facilitate proper coagulation. While traditional, we’ve added precise temperature monitoring and timing controls.

- Controlled Heat Method: Our preferred approach uses calibrated kettles to heat milk to exactly 60-65°C, followed by culture and acid addition. This gentler process gives us better repeatability and consistency across commercial batches.

Every heat treatment cycle is logged with calibrated instruments and documented in our batch records for complete quality assurance.

Step 4: How We Create Curds Through Coagulation

We transform liquid milk into solid curds through our carefully controlled coagulation process:

- Acidification: We use food-grade lactic acid cultures combined with natural acids (lime or lemon juice), just as traditional makers do

- Salt incorporation: We add precise amounts of salt for flavor and natural preservation

- pH monitoring: We track coagulation timing and pH to specific setpoints that balance our yield requirements with the final hardness dogs need

- Process documentation: Every step is monitored and recorded to ensure consistent curd formation

Step 5: Our Draining, Pressing, and Shaping Process

Once we’ve formed proper curds, we remove whey and create the dense texture that characterizes our chews:

- Initial draining: We ladle curds into clean cloth following traditional methods, allowing natural whey separation

- Controlled pressing: Using sanitary presses with measured pressure (replacing the stones traditional makers use), we press curds for exactly 24 hours

- Drainage monitoring: We maintain complete logs of whey removal to ensure consistency across batches

- Precision shaping: We trim pressed blocks into chew blanks sized acco

Step 6: How We Build Hardness Through Drying and Smoking

This is where we create the durability that makes our chews effective for extended dog enjoyment:

- Our Drying Environment: We use specially designed low-temperature, high-airflow rooms that remove moisture while preserving the cheese’s structural integrity. For select product lines, we also utilize traditional smoking houses that add flavor complexity.

- Our Timeline Management: While traditional methods suggest 10-15 days of sun-drying or 10 days of smoke-drying, we base our timing on water activity measurements rather than arbitrary schedules. This ensures consistent safety and quality regardless of environmental conditions.

- Continuous Monitoring: We track environmental conditions throughout the drying process, ensuring every chew in a batch receives identical treatment.

Step 7: Our Conditioning and Aging Process

After primary drying, we condition our chews for additional days to weeks. This step, often overlooked by other manufacturers, is crucial for:

- Moisture equalization throughout each individual chew

- Structural integrity that prevents cracking during use

- Optimal texture that dogs find most enjoyable

- Quality verification of water activity across every piece in the batch

Step 8: Our Finishing and Safety Treatments

We prepare each chew for safe use through:

- Edge finishing: We remove any sharp edges that could potentially harm dogs

- Size verification: We ensure every chew meets our specified dimensions

- Surface treatment: Select product lines receive UV-C surface treatment as an additional safety measure against surface contamination

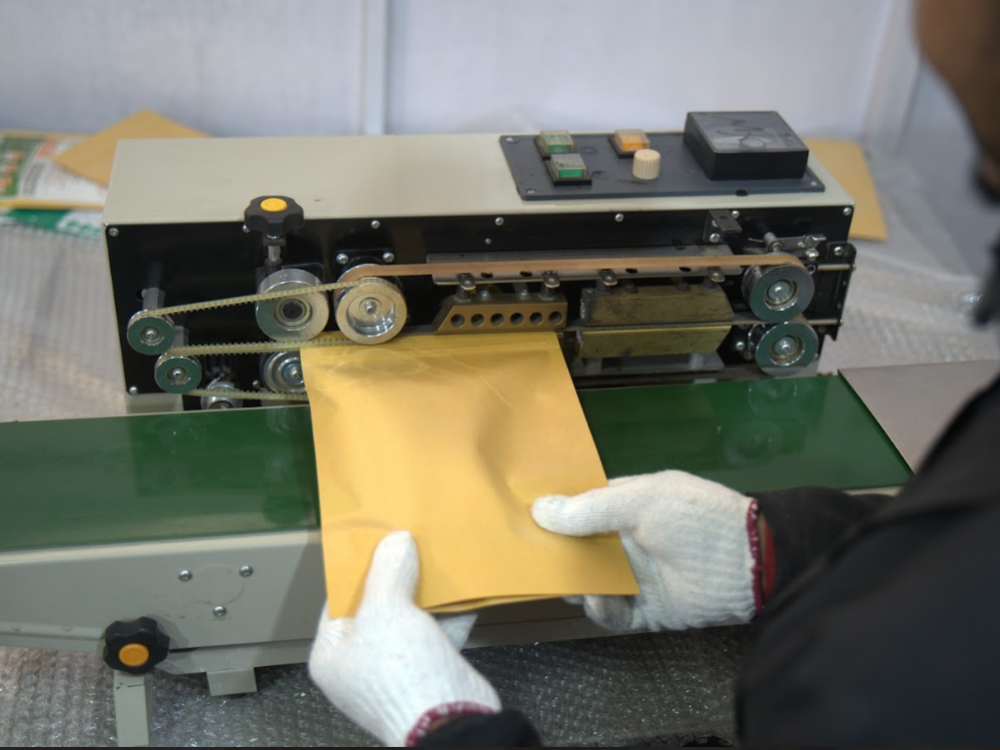

Step 9: How We Package for Long-Term Quality

Because we know chhurpi readily absorbs moisture from air, we’ve developed specialized packaging:

- Moisture barrier technology: We use multi-layer films that prevent humidity absorption during storage and shipping

- Active moisture control: We include desiccant packets in every package for additional protection

- Modified atmosphere: For export batches, we flush packages with nitrogen to remove oxygen and extend shelf life

- Complete traceability: Every package receives lot codes that trace back to the specific milk sources and production date.

Our Quality Control and Safety Standards

Why We Focus on Water Activity, Not Just Moisture

Our Science-Based Approach

While many manufacturers only measure moisture percentage, we also focus on water activity (aw) because it’s the measurement that actually determines safety. Microorganisms cannot grow below aw ~0.60, and dangerous pathogens like Salmonella require much higher water activity levels. We validate water activity ≤ 0.60 for every single lot as our critical control limit. This scientific approach ensures safety based on microbiology, not guesswork.

How We Handle Natural Variation

Research shows chhurpi’s moisture content can vary significantly (around 10% in controlled studies, with some traditional products showing even lower levels). Because chhurpi naturally reabsorbs moisture from the environment, we test every batch rather than assuming consistency.

Our Comprehensive Microbiology Testing

We test every finished batch for:

- Total viable count using validated methods

- Indicator organisms including coliforms and enterobacteria

- Specific pathogens: Salmonella, Listeria monocytogenes, and coagulase-positive Staphylococcus

- Results verification against pet food industry standards

We don’t release any batch until it passes every test.

How We Ensure Dental Safety

Our Hardness Testing Protocol

We follow veterinary dentistry guidelines using both instrumental testing and the practical “thumbnail test.” If our technicians cannot indent a chew with their thumbnail, we know it may be too hard for some dogs’ teeth. We carefully adjust our size, thickness, and curing parameters to balance durability with safety.

Size Matching Guidance We Provide

We include detailed size-matching recommendations on every package because we know that proper chew selection is crucial for dental safety. Our guidelines help pet owners choose appropriate sizes based on their dogs’ weight, age, and chewing habits.

Our HACCP System and Regulatory Compliance

We operate under a comprehensive Hazard Analysis and Critical Control Points (HACCP) plan that meets:

- FEDIAF Good Manufacturing Practices for European markets

- FDA Center for Veterinary Medicine requirements for U.S. distribution

- AAFCO standards for pet food safety and labeling

Our Critical Control Points Include:

- Heat treatment validation and verification

- Water activity confirmation at multiple process stages

- Pathogen absence verification before release

- Complete allergen labeling (milk products)

- Full lot traceability from source to consumer

What We Deliver: Nutritional Profile and Specifications

Our Typical Composition Results

Our hard chhurpi manufacturing process creates a distinctive nutritional profile:

- Concentrated protein from defatting and moisture removal

- Minimal fat content due to our cream separation process

- Very low moisture for natural shelf stability

- Natural minerals preserved from the original milk sources

We conduct proximate analysis on every lot because we know exact values vary with milk species, seasonal factors, and processing conditions. This testing ensures accurate labeling for every batch we produce.

How We Manage Natural Variation

We embrace the natural variation in yak chews while maintaining strict safety standards. Seasonal milk composition changes, weather variations during drying, and differences between source animals all contribute to the authentic character of our products. We manage this variation through flexible specifications that maintain safety while honoring traditional production realities.

Our Storage, Packaging, and Shelf Life Approach

Our Typical Composition Results

During Manufacturing: We maintain our bulk storage areas at approximately 8-10°C with controlled humidity to prevent moisture uptake and mold development during processing.

For Consumers: Our packaged products remain stable at room temperature when kept in original packaging, though we recommend cool, dry storage for optimal quality retention.

Our Advanced Packaging Technology

We’ve developed our barrier packaging system specifically to address chhurpi’s natural tendency to absorb moisture:

- Multi-layer moisture barrier films with validated transmission rates

- Sealed desiccant packets sized for specific package volumes

- Modified atmosphere packaging for our export products

- Tamper-evident sealing systems for consumer confidence

The Safety Information We Provide

Our On-Package Guidance

We include comprehensive usage instructions on all our packaging:

- Detailed size selection charts for different dog breeds and sizes

- Supervision recommendations for safe chewing sessions

- Choking prevention guidance through proper size matching

- Small piece management including when and how to remove end pieces

- Microwave puffing instructions for safely using small remaining pieces

Our Dental Safety Warnings

Following veterinary dental recommendations, we include specific guidance for:

- Dogs with aggressive chewing behaviors who may need supervised use

- Senior dogs with potentially compromised dental health

- Small dogs who might attempt to use oversized chews

- Proper selection based on individual dog characteristics

Why Our Manufacturing Approach Is Different

How We Combine Tradition with Science?

Our manufacturing philosophy respects traditional Himalayan methods while implementing modern food safety controls. We honor time-tested techniques like pressing and sun/smoke drying while adding instrumental monitoring for water activity and microbiology that most consumer information doesn’t even mention.

Our Commitment to Sourcing Transparency

Unlike manufacturers who treat sourcing as proprietary information, we openly share our milk species blending practices and cooperative partnerships. We believe transparency builds trust and ensures our practices align with both European and American pet food regulations.

How We Support Source Communities

We structure our purchasing to maximize benefit for the herder networks where yak chew production provides crucial income. This isn’t just ethical sourcing, it’s economic development that strengthens our entire supply chain while preserving traditional knowledge for future generations.